Milling minerals

Micrometer precision for milling minerals and other ultrafine targets

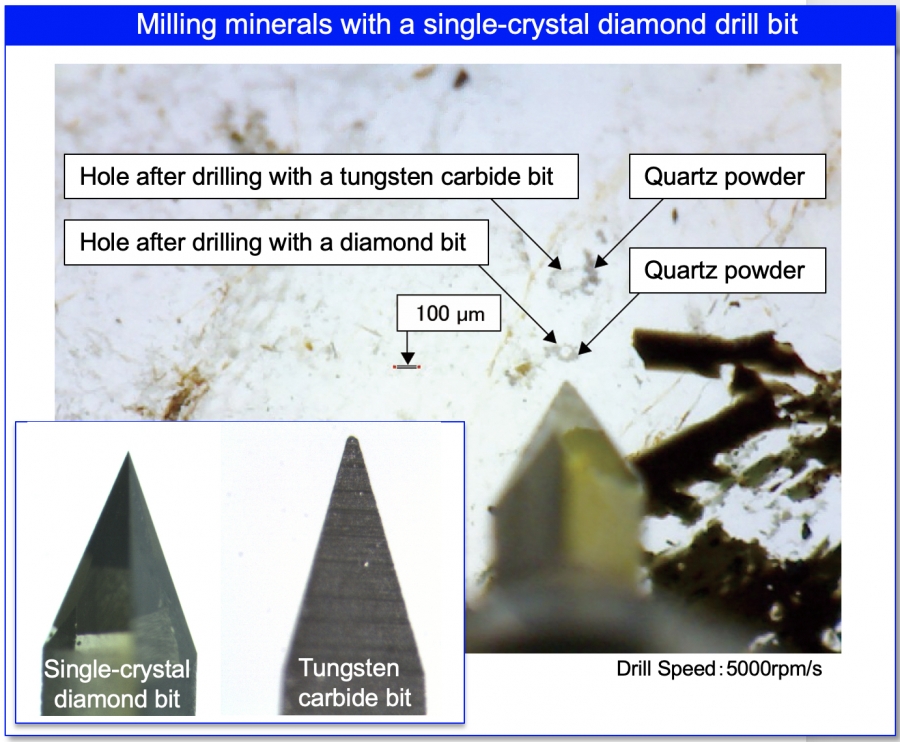

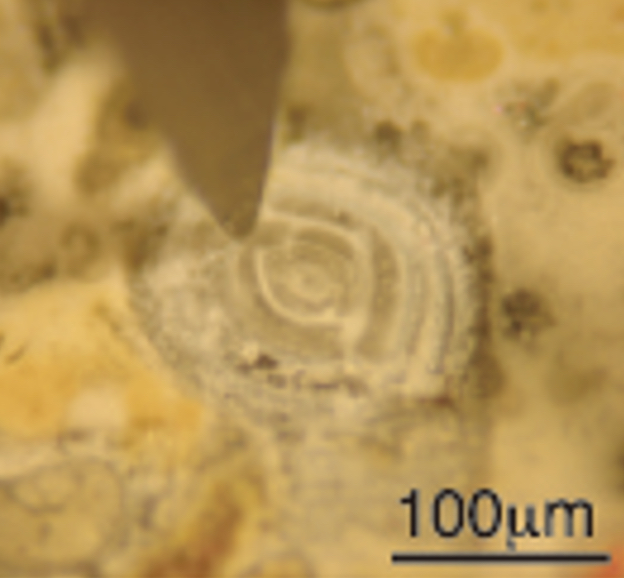

The figure at the bottom shows an example of using two drill bits to drill 10 µm perpendicular holes into a quartz grain in granite. Comparing the size of the hole drilled by the tungsten carbide bit that comes as standard equipment on Geomill326 and the hole drilled by our single-crystal diamond bit, we see that the hole drilled by the diamond bit has approximately 1/3 the diameter.

The tungsten carbide bit provides sufficient precision for most applications, but the extremely fine tip of the diamond bit makes it highly effective in applications that require drilling of very fine areas.

Compared with the extremely durable diamond bit, the tungsten carbide bit is also much more prone to wear. In applications where minerals and other hard materials must be milled, the durability of a diamond bit can offset its higher cost.

→ Please contact us for further information related to our single-crystal diamond bit.