Chapter 3: GEOMILL 326

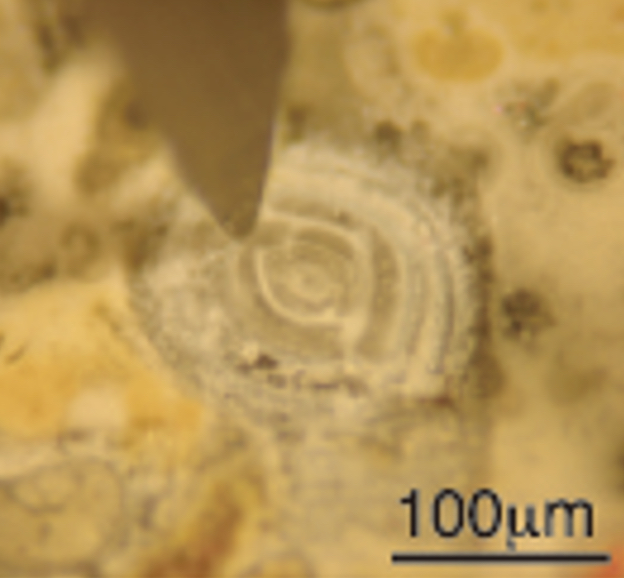

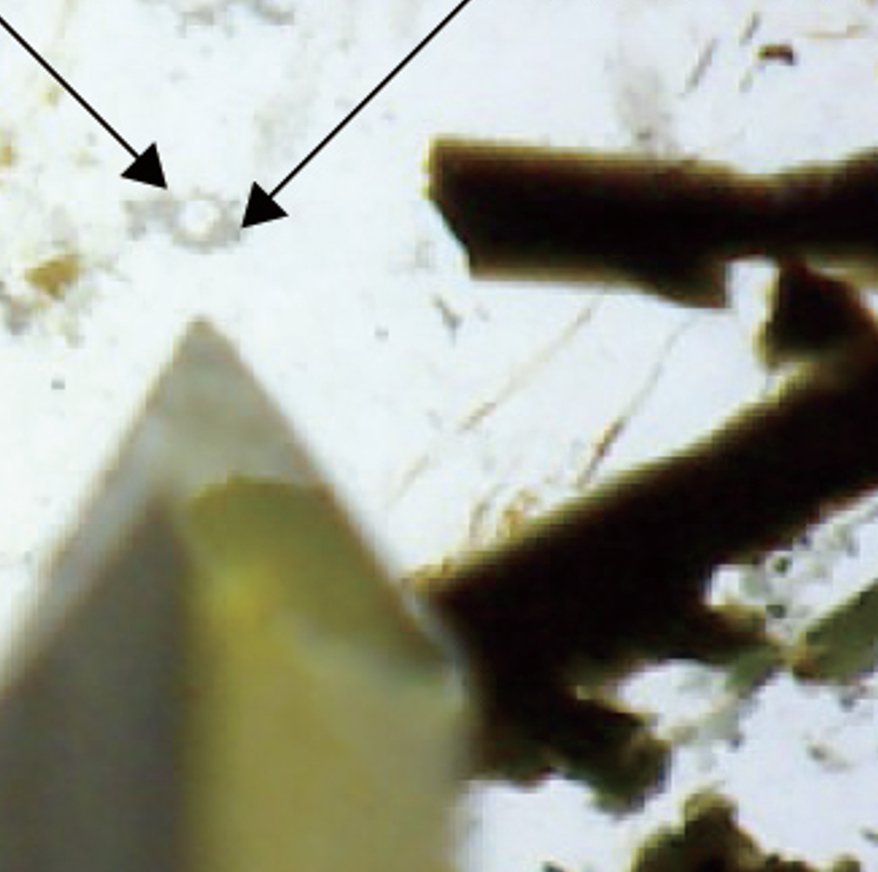

The GEOMILL326 set is comprised of: micro-drill, pedestal, CMOS cameras, lights and PC. Place the sample on the pedestal below the CMOS camera and observe on the PC monitor. For a more detailed view use the built-in zoom lens. If you specify the line to be cut on the screen, the coordinates are automatically changed. The drill is fixed; the base plate automatically moves along axis XYZ in 1μm increments for automatic precision cutting.

The portability, light weight and affordability of the GEOMILL326 are all points that Dr. Sakai picks out. "Whilst recently we've seen a number of other devices that can cut microscopic samples with lasers, these tend to be lacking in accuracy and are incredibly expensive. They're not the kind of thing that just anyone can use. I wanted something that an ordinary researcher such as myself could use." With the ability to set coordinates using Microsoft Excel the GEOMILL326 has both versatility and operability.

"The first responses we received having advertised the GEOMILL326 for sale on this site was "Can it cut metal?"- nothing to do with geology! The answer of course was "Yes". We also had a number of inquiries from other universities and research institutions regarding the drill - could we develop a range of drills bits to cut all manner of samples?!

The development of the micromilling system is continuing. For example, the collection of powder from samples for further analysis - these trace samples would be in the μm range, the kind of dust that would otherwise be blown away with a breath. We're nearing completion of a powder-recovery system, and filed a patent for it in 2007.

So what's next in the development of the GEOMILL326?

"We want to fully automate sample collection, so that we reach the stage where you simply specify the cutting coordinates, press 'Start' and go home. The next morning, your sample is ready for you in a bottle."

The GEOMILL326 set is comprised of: micro-drill, pedestal, CMOS cameras, lights and PC. Place the sample on the pedestal below the CMOS camera and observe on the PC monitor. For a more detailed view use the built-in zoom lens. If you specify the line to be cut on the screen, the coordinates are automatically changed. The drill is fixed; the base plate automatically moves along axis XYZ in 1μm increments for automatic precision cutting.

The portability, light weight and affordability of the GEOMILL326 are all points that Dr. Sakai picks out. "Whilst recently we've seen a number of other devices that can cut microscopic samples with lasers, these tend to be lacking in accuracy and are incredibly expensive. They're not the kind of thing that just anyone can use. I wanted something that an ordinary researcher such as myself could use." With the ability to set coordinates using Microsoft Excel the GEOMILL326 has both versatility and operability.

"The first responses we received having advertised the GEOMILL326 for sale on this site was "Can it cut metal?"- nothing to do with geology! The answer of course was "Yes". We also had a number of inquiries from other universities and research institutions regarding the drill - could we develop a range of drills bits to cut all manner of samples?!

The development of the micromilling system is continuing. For example, the collection of powder from samples for further analysis - these trace samples would be in the μm range, the kind of dust that would otherwise be blown away with a breath. We're nearing completion of a powder-recovery system, and filed a patent for it in 2007.

So what's next in the development of the GEOMILL326?

"We want to fully automate sample collection, so that we reach the stage where you simply specify the cutting coordinates, press 'Start' and go home. The next morning, your sample is ready for you in a bottle."